8:30 AM - 6:00 PM

- CNC Machines

- Apps

- Support

- Company

- Contact

- Blog

8:30 AM - 6:00 PM

4 axis EPS CNC router machine is used for EPS molding, aluminium mold, wood mold, automotive foam mold, aviation mold, trains mold, 3D musical instruments, bumper, bonnet interior trim mold.

Configurations of 4 Axis EPS CNC Router Machine:

1. Working area is 1300*2500*600mm.

2. Italy HSD Spindle 9.0kw air cooling spindle.

3. Taiwan Syntec controlling system.

4. Japan Yaskawa servo motor and drivers.

5. Delta inverter from Taiwan.

6. Taiwan HIWIN square rails.

7. Japan Omron limited switch.

8. Divided structure bed structure, Fixing with screws.

9. Working table:T-slot working table.

10. Japan Shimpo reducer.

Technical Parameters of 4 Axis EPS CNC Router Machine:

| Model | STM1325-4 Axis |

| X,Y Working Area | 1300×2500mm |

| Z Working Area | 600mm |

| Resolution | 0.5mm |

| Repositioning Accuracy | 0.5mm |

| Lathe Structure | Seamless welded steel structure, better than cast iron one |

| X,Y Structure | Rack and pinion transmission, Hiwin square guide rail |

| Z Structure | Germany-made rolling ball screw, Hiwin square guide rail |

| Max. Idling Speed | 30m/min |

| Spindle | 9kw HSD spindle |

| Spindle Rotate Speed | 0-24000r/min, variable speed |

| Working Voltage | AC380V/50Hz |

| Working Mode | YASKAWA Servo motor and diver |

| Command | G code (HPGL,U00,mmg,plt) |

| Operating System | Syntec control system |

| Diameter of cutter | φ3.175-φ12.7mm |

| Cooling Mode | Air-cooling |

| Work-holding | By clamp |

| Net Weight | 3000KG |

| Software | Type 3, ArtCam, Ucancam |

Advantages of 4 Axis EPS CNC Router Machine:

1. Whole working table cast by resin sand. The annealing and other heat treatment methods ensure that the whole structure is tested to the limit for sturdiness and reliability.

2. Italian high-speed spindle, with top speed of 18000rpm, guaranteering maximum processing efficiency and productivity.

3. It adopts imported ball bearing, widening linear guide rail, self-lubricating sliding block. When engraving, equal force in all directions, to ensure the accuracy and strength.

4. Taiwan Syntec controller can read the codes in an efficient manner. On-line simulation and monitoring function are available. Processing efficiency and safety are guaranteed.

5. All of these models can be customized according to customer requirements.

Applications of 4 Axis EPS CNC Router Machine:

4 axis EPS CNC router machine can work on aluminium mold, wooden mold, EPS and non-metallic carbon materials, automotive foam mold, aviation mold, trains mold, 3D musical instruments, bumper, bonnet interior trim mold.

Detail Pictures of 4 Axis EPS CNC Router Machine:

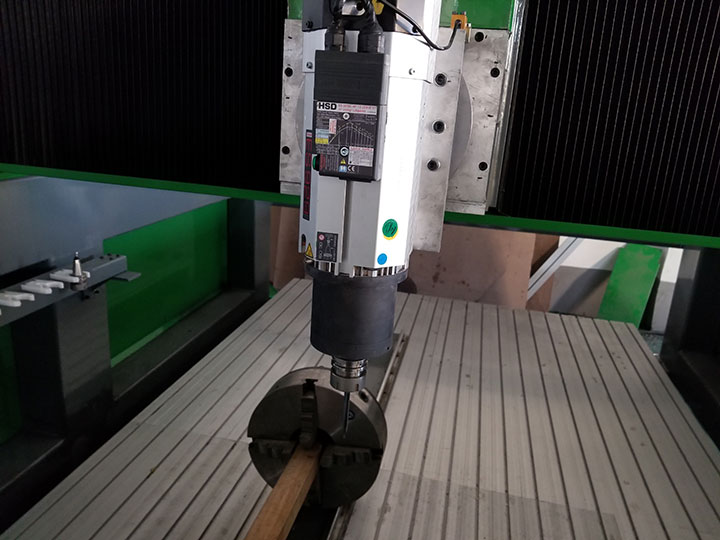

Italy HSD Spindle 9.0kw air cooling spindle:

Taiwan Syntec control system:

Japan YASKAWA servo motor:

Linear ATC tool magazine:

Rotary device:

Samples of 4 Axis EPS CNC Router Machine:

Everything as expected. Arrived from China in 30 days. Assembly is pretty straightforward. Learning to use the CNC foam router has a short learning curve with the instructions came with it.