8:30 AM - 6:00 PM

- CNC Machines

- Apps

- Support

- Company

- Contact

- Blog

8:30 AM - 6:00 PM

Automatic feeding CNC machine for panel furniture production line is used with automatic feeding, nesting, cutting and optimization, playing vertical hole, automatic cutting coherent, continuous processes.

Advantages of Automatic Feeding CNC Machine with Panel Furniture Production Line:

1. Automatic feeding, cutting and optimization, playing vertical hole, automatic cutting coherent, continuous processes, maximize efficiency output.

2. User-friendly machine control interface design. Workers can operate the machine expertly just by simple training. High efficiency of the machine help you achieve productivity leap.

3. We adopt high quality spare parts for this CNC machine such as Italian HSD Spindle, YASKAWA AC Servo system, German Becker Pump, and so on. It adopts stable performance.

Applications of Automatic Feeding CNC Machine with Panel Furniture Production Line:

1. Furniture: Cupboard, wardrobe, panel furniture, office furniture, solid wood furniture, wood door, table, chair, door and window.

2. Woodwork: Sound box, game machine box, computer desk, sewing machine table and musical instrument.

3. Panel machining: Insulating parts, plastic and chemical parts, PCD, inner body of bullet train, bowling ramps and stairways, carbonization mixtures such as compact board, phenolic resin, epoxy resin, ABS, PP and PE.

4. Decoration industry: Carving, milling and cutting processing of acrylic, PVC, density board, artificial stone, PMMA, plastic and soft metal plates including copper plate and aluminum plate.

Features of Automatic Feeding CNC Machine with Panel Furniture Production Line:

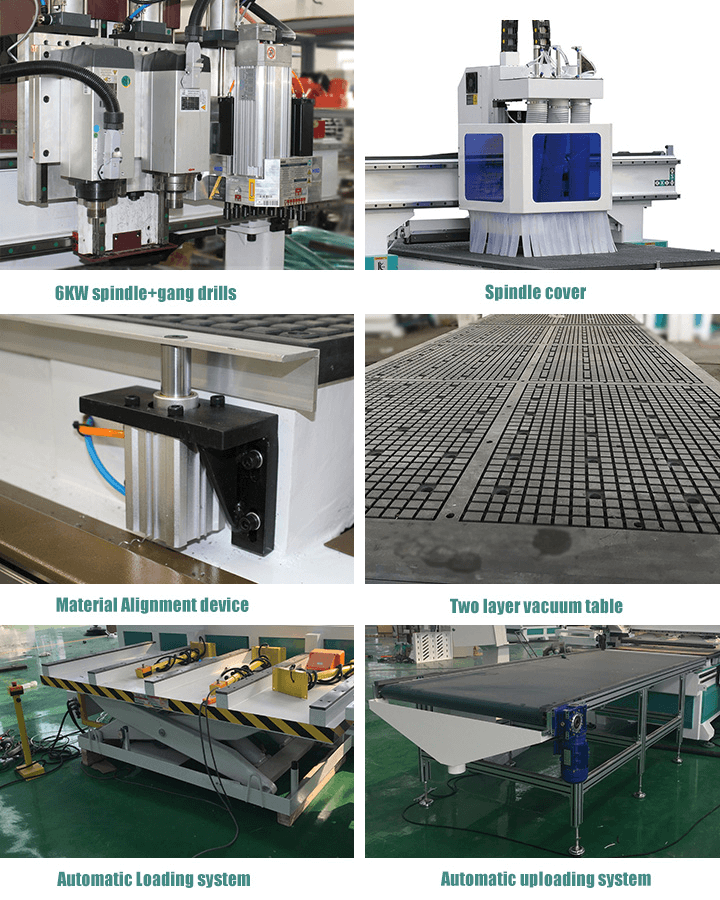

1. Highly automated nesting solution with automatic loading and unloading system. The complete work cycle of loading, nesting, drilling and unloading is carried out automatically, which results in maximum productivity and zero down time.

2. Humanizing design of the machine control interface,very simple to operate, requiring only minimal training of operator, do not need specialized operation technical personnel, high efficiency.

3. World‘s first class components - Italian high-frequency electro spindle, Taiwan SYNTEC control system, German servo motors and drivers, high precision planetary gear reducers, stable performance and long service life.

4. The world leading vacuum table, high adsorption capacity, can be strong adsorption of materials of different sizes, density, no deformation.

5. Truly versatile-nesting, routing, vertical drilling, carving, side milling and edge grinding all in one. It is well-suited for panel furniture, office furniture, cabinets production.

Technical Parameters of Automatic Feeding CNC Machine with Panel Furniture Production Line:

| Model | S3 | ||

| Working Travel | X axis | 1300mm | |

| Y axis | 2500mm | ||

| Z axis | 200mm | ||

| Table Structure | Vacuum suction | ||

| Orbit | HIWIN or PMI square orbit | ||

| Transmission Type | X,Y Rack, Z Ball screw | ||

| Working accuracy | ±0.05 | ||

| Re-positioning accuracy | |||

| Max air move speed | 25000mm/min | ||

| Max working speed | 12000mm/min | ||

| Spindle parameters | Type of cooling | Air cooling spindle | |

| Power | 6KW | ||

| Speed | 0-24000r/min | ||

| Inverter | Delta Inverter | ||

| Drive system | 850W Japan Yaskawa servo | ||

| Command code | G code | ||

| Software | Type3 software, Wentai software,Artcam software | ||

| Running circumstance | Temperature: 0°C~45°C,Relative humidity: 30%~75% | ||

| Control system | Taiwan Syntec control System | ||

| Oiling system | Automatic | ||

| Working voltage | AC380V/3PH/50HZ | ||

| Net Weight | 3500kg | ||

Automatic Feeding CNC Machine with Panel Furniture Production Line Projects:

Package and Service for Automatic Feeding CNC Machine with Panel Furniture Production Line Projects:

1. Packed the CNC machine with plastic sheet for clearing and damp proofing.

2. Then put the CNC machine in the plywood case for safety and clashing.

3. Transport the plywood case into the container.

Guarantee and Service

1. 12 Months warranty under normal use and lifelong maintenance we supply.

2. 24 hours technical support by phone, email and other online contact.

3. Free training on machine operation, daily maintenance and basic program designing in our factory.

4. Friendly English operation manual.

Delivery Time

Usually, for normal model, within 30 days after get the deposit.

Payment Terms

T/T in advance

L/C is allowed if the amount is big. Please issue the L/C draft for our configuration first.

Other payments we can consider if acceptable for us.

Nice product, quickly delivery, and excellent user support. STYLECNC team is very good.