8:30 AM - 6:00 PM

- CNC Machines

- Apps

- Support

- Company

- Contact

- Blog

8:30 AM - 6:00 PM

Most profitable 5x10 fiber laser metal cutting table with power options from 1000W to 12000W features with higher cutting speed and quality compared to traditional metal cutting tools, which comes with an CNC controller to automate metal fabrication, and an up and down exchange platform to finish the platform exchanging within 15s for commercial use.

Profitable CNC fiber laser cutting table ST-FC3015GC is upgrade model of ST-FC3015C.

| Model | ST-FC3015GC |

| Laser source | IPG (Raycus, MAX for Option) |

| Fiber laser power | 1000W (1500W, 2000W, 3000W, 4000W, 6000W, 8000W, 12000W for Option) |

| Working size | 3000*1500*290mm |

| X and Y axis positioning accuracy | ±0.03mm |

| X and Y axis repositioning Accuracy | ±0.02mm |

| Max moving speed | 80m/min |

| Max acceleration | 1.0G |

| Max load of work table | 700 Kgs |

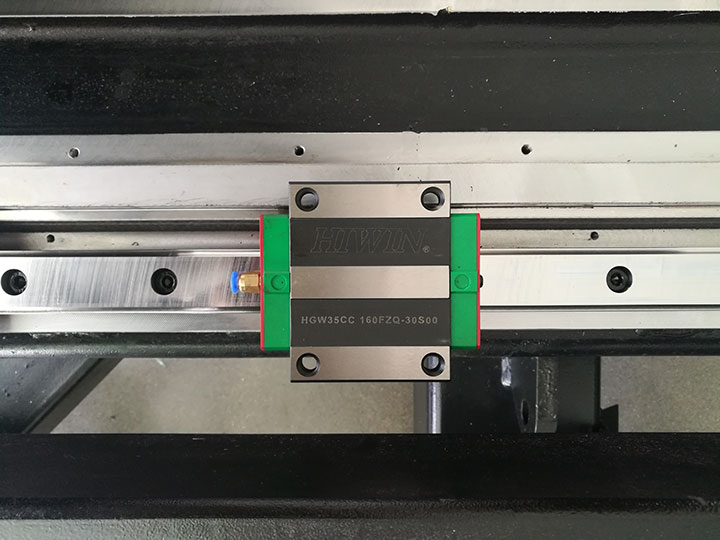

| Transmission Way | Double servo motor and Hiwin square rails 35mm |

| Machine Size | 8050*2660*2160mm |

| Machine Weight | 5500 Kgs |

| Rotary | Optional (3m or 6m can customized) |

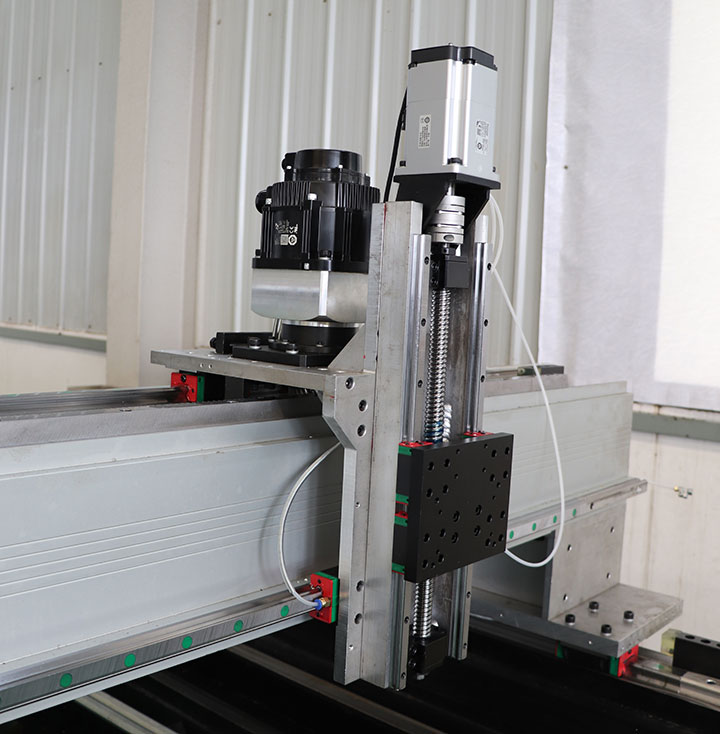

Aviation Aluminum Gantry of CNC fiber laser metal cutting machine

Swiss Raytool laser cutting head: (different power match different model)

Cypcut control system with PC controller

Heavy Duty machine frame, milling by 5 axis CNC milling machine to keep stable and precision.

Independent electronic control cabinet with air conditioner, It can avoid the electromagnetic radiation affect the mechanical parts running.

High precision Taiwan TBI ballscrew and Hiwin Square Rails, Z axis drived by servo motor.

Taiwan Hiwin square rails, slider with flange, high accuracy, zero-distance to avoid the dust accumulation.

Laser metal cutting machine can choose rotary device for cutting metal tubes.

ST-FC3015GCR

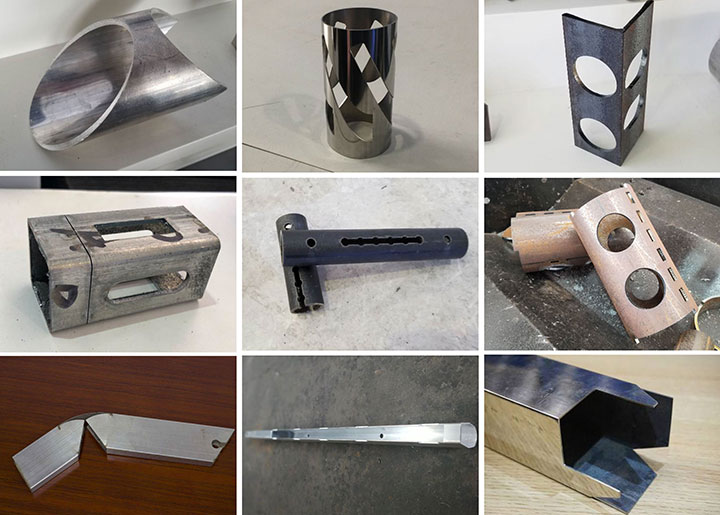

Application Materials

CNC fiber laser cutting system is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, etc.

Application Industries:

CNC fiber laser cutting systems are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

1. Strong water resit bottom in plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed.

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard protective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

1. Free sample cutting service:

For free sample cutting/testing, please send us your CAD file (.plt or .ai), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

2. Progressing Solution Design:

According to customer’s product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

3. Customized machine design:

According to customer's application, we may revise our machine according to customer's convenience and high production efficiency.

1. We will supply the laser machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote,such as TeamViewer, E-mail, Telephone, Mobile, Whatsapp, Skype, 24/7 online chat, and so on, when you meet some problem of installation, operation or adjusting. (Recommended)

2. You can come to our laser machine factory for training.We will offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools and testing facility. Training Time: 3~5 days (Recommended)

3. Our engineer will do a door-to-door instruction training service at your local site. We need your help to deal with the visa formality, prepaid traveling expenses and accommodation to us during the business trip and service period before their dispatch. It's better to arrange a translator (if no English-speaking) for our engineers during the training period.

1. 3 years for the whole machine, laser device 18 months, chiller 12 months, lens/mirror/nozzle without warranty.

2. Long life-time maintenance, after-sale department will offer 24/7 English online support.

3. Except the damage artificially, we are responsible for offering the fittings free of charge during warranty.

4. After the warranty period expired, the buyer only need to pay the actual maintenance cost.

5. Certificate support: CE, FDA, SGS.

If you have an idea to get a free quotation of the profitable CNC fiber laser cutting machine, please answer the questions as following and tell us by email, so that we can recommend the most suitable laser machine and quota the affordable price to you directly.

1. Do you need to cut metal sheets/plates, metal pipes/tubes only or both?

2. If need to cut tubes, What is your tube length, diameter and max thickness?

3. For cutting metal sheet, what is the max working area required?

4. After processed, what the materials will be used for? (Applications)

5. Which seaport is the nearest to you?

6. Do you have any experience in the fiber laser metal cutting table?

7. What is your online chat way? Such as Skype and Whatsapp.

8. Are you an end user or reseller?

This machine is a star. I am glad that I found this metal cutting machine and it is really convenient for my sheet metal cutting works with the exchange table, it made the whole process much more simple. I like it.